Contents

Why Sensory Silicone Toys Play Matters

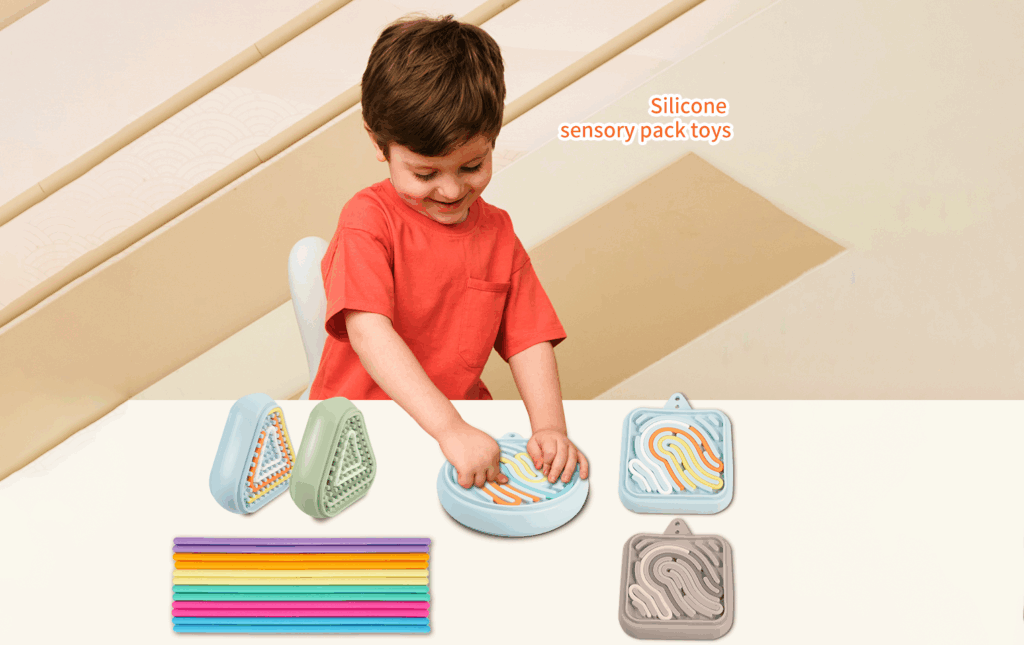

Neuroscience shows that 0-6 years are critical for brain development. Our toys transform this window into tactile learning adventures that:

✔️ Build neural connections through texture exploration

✔️ Develop fine motor skills with squeeze-and-stretch action

✔️ Reduce screen time with self-directed play

The Problem with Ordinary Toys

Safety Shortcomings

🚫 *”Many mass-market toys fail basic safety checks”*

-

Cheap plastics with phthalates and lead paint

-

Small parts that pose choking hazards

-

Fading colors that flake into mouths

Developmental Gaps

🚫 *”One-dimensional toys limit learning potential”*

-

Static designs that bore quickly

-

Missed opportunities for multi-sensory stimulation

Our Science-Backed Solution

Certified Safe Materials

-

Medical-grade silicone (complies with FDA 21 CFR 177.2600)

-

Non-porous surface resists bacteria buildup

-

Bite-proof durability even for teething babies

Smart Sensory Features

| Developmental Benefit | Our Innovation |

|---|---|

| Tactile Discrimination | Various texture boards |

| Auditory Processing | Pressure-activated chime modules |

| Color Recognition | FDA-approved gradient dyes |

Why Consumers And Manufacturers Choose Us

As a powerful factory focusing on the research and development and production of silicone products for 25 years, we have become a long-term partner of many well-known maternal and child brands around the world with the following core advantages:

Full industry chain production, quality controllable

We independently control the entire process from raw material procurement → mold development → production → quality inspection → packaging to ensure that each batch of products meets high standards.We have a 100,000-class dust-free workshop to avoid pollution during the production process.

Advanced technology, precise quality control

Using liquid silicone injection molding (LSR) and platinum vulcanization technology, the product is purer and more durable.Each batch of products undergoes multiple quality inspection processes including tensile testing, color fastness testing, and chemical substance testing.

Support customized services

OEM/ODM cooperation model, the shape, color, hardness, packaging, etc. can be customized according to customer needs.Provide private model development services to help brands create differentiated products.

Fast delivery, worldwide supply

The monthly production capacity is more than 500,000 pieces, supporting small and medium batch flexible orders. Cooperating with international logistics such as DHL and FedEx to ensure efficient delivery for global customers.

![]()

Global Compliance Ready

📌 Pre-certified for:

-

EU (EN71, REACH)

-

USA (ASTM F963, CPSIA)

-

Australia/New Zealand (AS/NZS ISO 8124)

Proven Market Success

⭐ Amazon’s Choice in 5 countries

⭐ Featured in 300+ Montessori programs

⭐ 35% repeat order rate from wholesalers

Partner With Confidence

We help brands:

✅ Differentiate with patented textures

✅ Scale faster with MOQs from 500 units

✅ Simplify logistics with prepackaged FBA kits

Get Started Today:

📞 Call: +86 134 2097 4883

📧 Email:sale11@lyasilicone.com

🌐 Visit:www.lyasilicone.com