Silicone compression molding products

Shenzhen LYA Silicone Rubber Products Co., Ltd.

Founded in 2001, located in Baohua Industrial Zone, Longhua Town, Shenzhen, it is a comprehensive enterprise specializing in the design, research and development, production and sales of silicone rubber products.LYA Silicone has been engaged in foreign trade processing and manufacturing services in the silicone rubber products industry for more than 20 years. We have experienced staff, team management, quality control, research and development capabilities, project management,sales management and other services related to silicone rubber. Our company has more than 5000 silicone products project development experience.

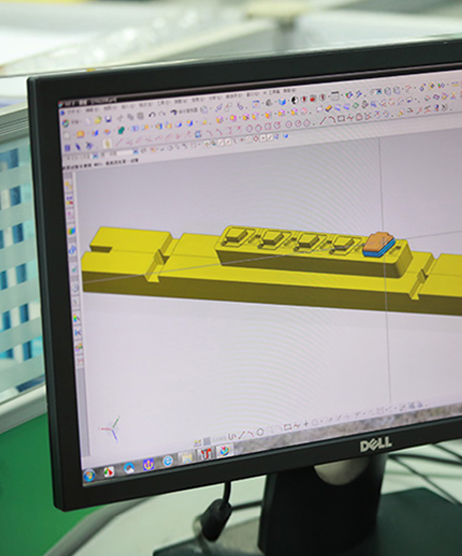

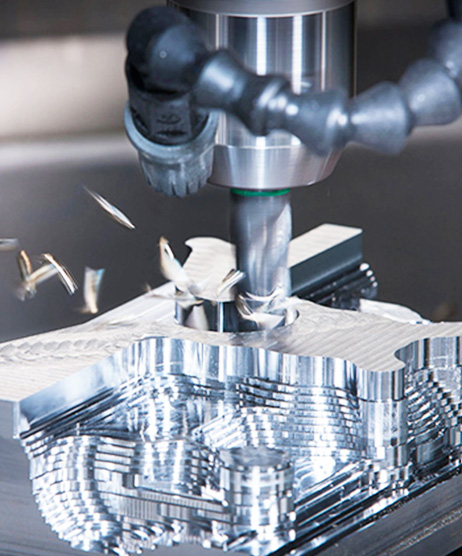

It is a professional OEM/ODM comprehensive design developer of silicone products, and a production and processing manufacturer integrating sales and service. Our company pays special attention to the quality of products and the control of the surrounding production process. We have two sets of advanced CNC mold processing and manufacturing centers, 20 sets of automatic solid-state molding and vulcanization equipment, silk screen equipment, liquid injection equipment, laser engraving equipment, infrared irradiation equipment, 50 sets of high-precision measuring instruments. We strictly follow the ISO9001 quality standards to regulate our product production and quality control, all of our products meet FDA, LFGB, SGS, ROHS.UL and related environmental standards.

In recent years, we have applied for our own product patents, and have also won the Shenzhen High-tech Enterprise Certificate and the National High-tech Enterprise Certificate. It has cooperated with many top 500 enterprises in China, and foreign customers are located in Europe, America, Japan and South Korea.

Our quality management system includes incoming material control, process control and shipment control. Each of these three controls has a complete flow chart. We strictly Follow this procedure.

Process: from purchasing raw materials-mixing-molding-secondary vulcanization-sample test = qualified sample

The main processing techniques are: liquid molding, extrusion molding, and compression molding. Among them, the process in the industry Compression molding is the most common, because molded silicone products are relatively widely used.

Voice of Customers

Shorten the time of non-standard production process, stable delivery and quality assurance.

On time

Rubber making room

Model room

Molding workshop

Operation of molded products

Liquid silicone injection molding machine

Product testing room

WHY CHOOSE US

LYA focusing on silicone OEM products production over 20 years, wholeheartedly provide you with the best quality silicone products!

Suppose you have a very special project, an idea which is very special and unique, and has great potential in the market.Then you should talk to us!

You can show us your silicone product photos and two-dimensional drawings, and tell us these parameters, such as length, width, height, diameter, thickness, weight, etc. Then our excellent design team will help you solve the problem.

You can also provide us with your samples.On this basis, we can help you convert them into 3D drawings. After that, we will help you make molds and make samples for you.

If any of the 3 steps are valid and you confirm the samples we made, then you can place an order. We will immediately help you with mass production!

FAQ

We are a professional OEM manufacturer of silicone products, established on June 4, 2001

A sort of. Inquiry—provide us with all clear requirements.

2 Quotation—Official quotation sheet with all clear specifications.

C. Payment terms—100% advance payment before mold development

T/T 30%, the balance is based on the copy of the bill of lading

d. Develop molds—open molds according to your requirements.

e. Sample confirmation—After the sample is made, the sample will be sent to you for confirmation

f. Production—Bulk order production

g. Transportation —by sea, air or express. Detailed pictures of the packaging will be provided.

A: Honestly, it depends on the quantity of the order and the season in which you placed the order.

MOQ’s delivery time is approximately 35 days. Generally speaking, we recommend that you

Inquiry starts two months before the date.

A: We accept FOB, CFR, CIF, EXW, DDP, DDU, express etc. You can choose the most convenient or cost-effective one.

contact

Custom Silicone Mold Manufacturer

If you have any requirements for silicone products customization, please contact us immediately…

- sale11@lyasilicone.com

- +86-13420974883

- New Building 2, Baohua Industrial Zone, Longfeng 1st Road, Longyuan Community, Longhua Street, Longhua District, Shenzhen